Sustainability That Works: Pigment Wetting

It’s easy to root for sustainable materials. Who wouldn’t love the idea of paints and coatings made from sunflowers or soybeans instead of fossil fuels? But when it comes to actual performance, many professionals still raise an eyebrow. Sustainability needs to work – and we’re here to show you where it already does work.

The Dilemma: Viscosity vs. Pigment Wetting

High-solid coatings are a balancing act. To reduce VOCs and solvents, formulators rely on low molecular weight binders. But low molecular weight often comes at the cost of reduced functional group content, which can weaken pigment wetting and dispersibility.

The Hypothesis: Can Merginols Bridge the Gap?

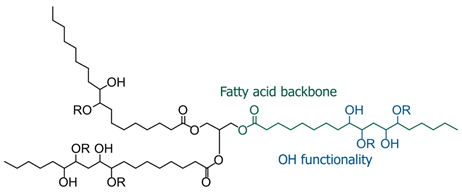

Merginols are plant oil–based polyols with a structure that combines the fatty acid backbone of alkyds with the polar hydroxyl functionality typical for acrylates. This hybrid nature suggests they might offer sufficient anchoring sites for pigments even though the molecular weight is relatively low.

Figure 1 Representative chemical structure of Merginols, showing the hybrid nature of a fatty acid backbone (alkyd-like) and hydroxyl functionality (acrylate-like).

In theory, they should match or outperform conventional binders in pigment wetting and dispersibility, while maintaining the low viscosity required for high-solid or solvent-free systems. We put that to the test.

What We Tested

Binders:

- Merginol 909 and Merginol 240 (plant oil-based polyols)

- Setal 301 SM 83 (long oil alkyd resin)

- Macrynal SM 2703/80 BACX (hydroxyl-functional acrylic resin)

Pigments:

- Chromium Oxide Green (inorganic, easy to disperse)

- Hostaperm Blue (organic, phthalocyanine blue, hard to disperse)

Dispersion method:

All formulations were prepared using a high-speed dissolver (25.2 m/s tip speed, 5 minutes). No bead milling. Each formulation contained binder, defoamer, dispersing agent, and pigment. Merginol systems included an accelerator; the alkyd system used a siccative.

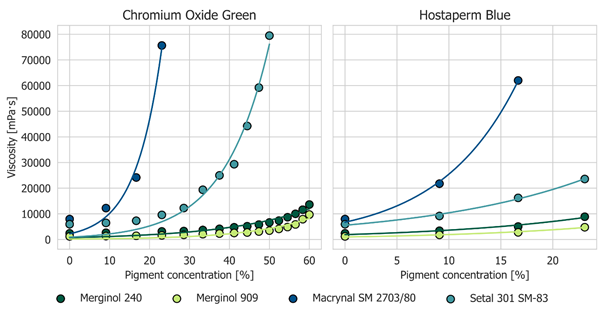

Viscosity: The First Advantage

Out of the box, the hydroxyl-functional acrylic resin was supplied as an 80% solution in butyl acetate/xylene, with a viscosity of 8000 mPas. The long oil alkyd resin was supplied at 80% in mineral spirits and had a viscosity of 6000 mPas.

By contrast, Merginol 240 and Merginol 909 were used without any solvents and delivered viscosities of just 2400 mPas and 1200 mPas, respectively.

That means higher pigment loadings are possible straight away, without dilution as shown below.

Figure 2 Viscosity of binders as a function of pigment concentration. Plant-based binders (Merginols) maintain low viscosity even at high pigment loadings – without the need for added solvents.

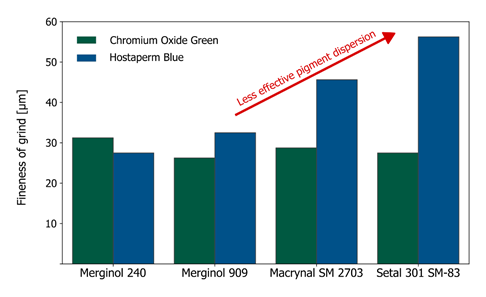

Better and Faster Dispersion: The Second Advantage

For the inorganic pigment, fineness of grind was similar across all binders (~30 µm). However, with the more challenging organic pigment, Merginol-based systems clearly outperformed their petrochemical counterparts, achieving finer dispersions withina the same time.

Figure 3 Fineness of grind after 5 minutes of dispersion. All binders perform similarly with the inorganic pigment, but Merginols outperform petrochemical binders with the organic pigment.

Better Surface Quality: The Third Advantage

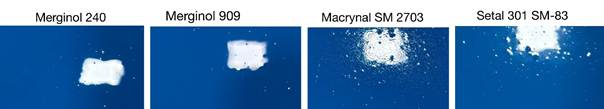

These dispersion advantages translated directly into surface appearance. Formulations based on Merginols produced smooth, high-gloss films. In contrast, the alkyd and acrylic systems showed visible pigment agglomeration, orange peel, pinholes, and other surface defects.

Figure 4 Surface appearance of dried films with Hostaperm Blue. Merginol-based systems yield smooth, glossy films, while conventional binders show visible defects such as orange peel and agglomeration.

The Bottom Line

Yes, there are still areas where biobased materials may fall short. But there are also clear cases where they outperform traditional options and pigment wetting is one of them.

If you haven’t tried making a pigment paste with Merginols, now’s a good time to start.

Further reading

Also take a look at the general performance of bio-based polyols here.