Bio-based Polyols

Sustainable Alternatives from Nature

Polyols are essential building blocks in coatings, adhesives, foams, and sealants. Traditionally, they have been sourced from petroleum-based raw materials. But not at HOBUM. Here we have developed Merginol: a portfolio of biobased polyols derived from soy, sunflower, and castor oil.

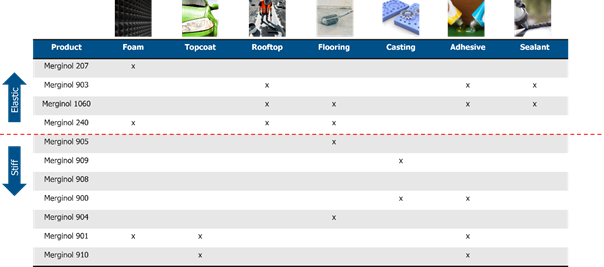

Application Areas

Our Merginol product line serves a diverse range of applications across multiple industries. From flexible foams to rigid topcoats, from rooftop coatings to sealants to industrial adhesives, Merginol offers sustainable solutions without compromising on performance.

Figure 1: Application areas for Merginol bio-based polyols across industries.

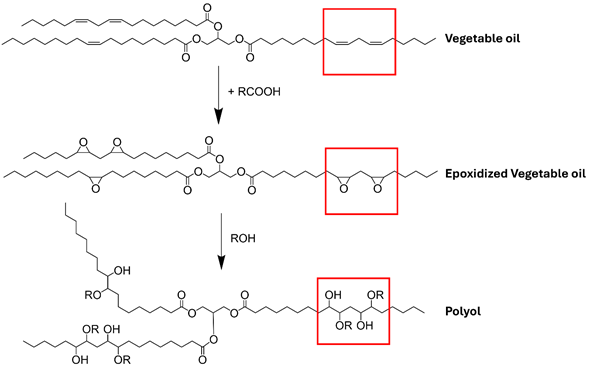

How Plant Oils are transformed into Bio-Based Polyols

Plant oils like soybean and sunflower naturally lack hydroxyl groups – the essential functional groups that make a polyol and that are necessary for the reaction with isocyanates to form polyurethanes. To add them, we employ a sophisticated two-step process:

- The double bonds of the oil are first epoxidized

- The epoxides are then reacted with alcohols to introduce hydroxyl functionality

Figure 2: Reaction mechanism showing the transformation of vegetable oils into Merginol polyols. The process involves epoxidation of double bonds followed by hydroxylation, introducing the functional hydroxyl groups

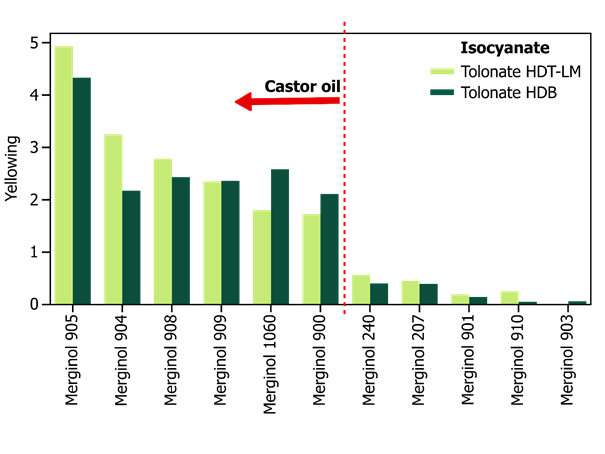

Castor oil is unique in that it already contains a hydroxyl group and thus needs no additional hydroxylation. Therefore, the double bond remains intact in these products. This creates a trade-off: castor oil-based polyols are less UV-resistant since these remaining double bonds degrade under UV exposure.

UV resistance

This is also what our testing shows. Soybean and sunflower oil-based polyols demonstrate excellent resistance to yellowing when exposed to UV light. Not so much the polyols that are based on castor oil. Merginol 910, 901, and 903 show the best UV stability.

Figure 3: UV resistance of Merginol variants measured by yellowing (change in b*) over time using a spectral photometer (Xrite). Lower values indicate better UV stability

Tailored Properties Through Refined Processing

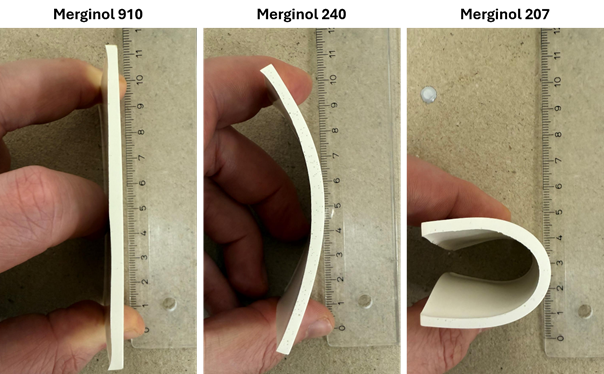

Beyond UV stability, our advanced refinement process for soybean and sunflower oil-based polyols enhances their versatility. By selecting specific alcohols during the hydroxylation process, we can precisely control properties:

- Merginol 910 offers exceptional hardness

- Merginol 240 and 207 provide excellent flexibility

All from the same oil base. This flexibility in processing allows us to create products with properties perfectly suited to many different applications.

Figure 4: Flexibility comparison of Merginol variants with different hardness profiles. Merginol 910 (left) maintains rigid properties, Merginol 240 (center) shows moderate flexibility, while Merginol 207 (right) demonstrates maximum flexibility, illustrating how the same oil base can yield polyols with dramatically different mechanical properties.

Finding Your Perfect Match

Choosing the right Merginol depends on the properties that matter most to you and your application. Here’s what you need to know:

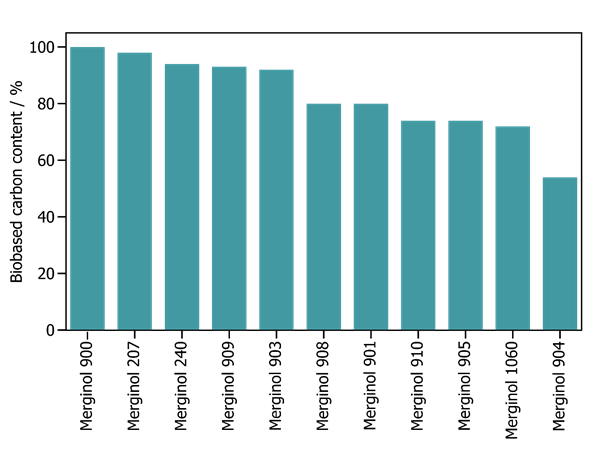

Biobased Carbon content

Sustainability is at the core of our products, and our Merginols feature impressive biobased carbon content:

- Near 100% biobased: Merginol 900, 208, and 207 lead the way with 95-100% biobased carbon

- High biobased content: Merginol 240, 909, and 903 contain 90-95% biobased carbon

- Moderate biobased content: Even our most modified products maintain a minimum of 50% biobased carbon

This high renewable content helps reduce your carbon footprint while maintaining performance properties.

Figure 5: Biobased carbon content of Merginol variants, showing the percentage of renewable carbon in each product. Merginol 900, 208, and 207 achieve nearly 100% biobased content, while even the most modified variant (Merginol 904) maintains over 50% renewable carbon content.

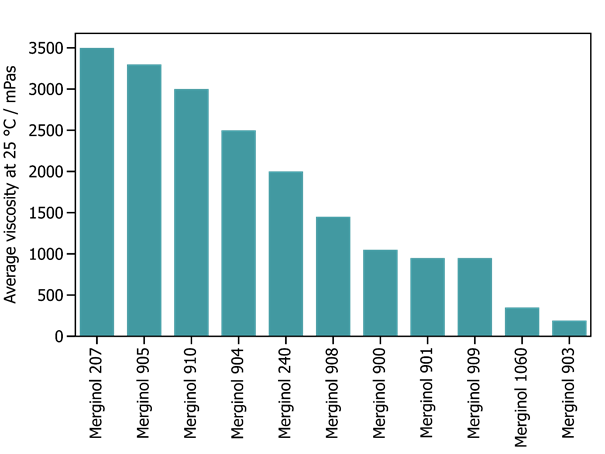

Viscosity Properties

The viscosity of a polyol significantly impacts processing and application characteristics. Our Merginol portfolio offers options across the full viscosity spectrum:

- High viscosity (>3000 mPas): Merginol 207 and Merginol 905

- Medium viscosity (1000-3000 mPas): e.g. Merginol 910, 904, and 240

- Low viscosity (<1000 mPas): e.g. Merginol 903 and 1060

These varied viscosity profiles allow you to select the perfect Merginol for your specific application requirements.

Figure 6: Viscosity measurements of Merginol variants at 25°C (mPas), showing the wide range from high-viscosity products like Merginol 207 (3500 mPas) to low-viscosity options like Merginol 903 (150 mPas), enabling selection of appropriate processing characteristics for specific applications.

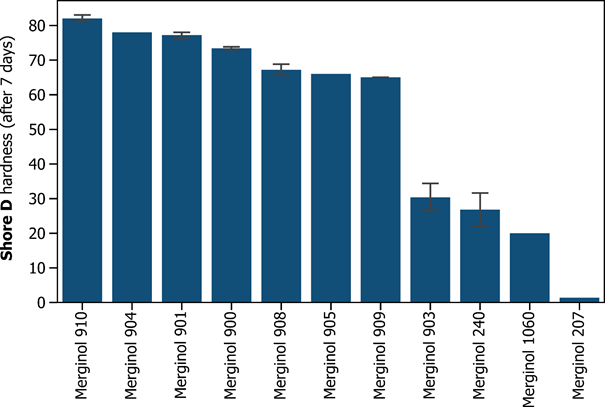

Hardness and Mechanical Strength

After 7 days of curing at room temperature with an MDI hardener, our Merginol products display a wide range of hardness values:

- High hardness applications: Merginol 910, 904, 901, and 900 lead the way with Shore D hardness values between 75-85

- Maximum flexibility: Merginol 240, 1060, and 903 are ideal for sealants

- Specialty applications: Merginol 207 is our most flexible polyol, primarily used in flexible foaming applications

Figure 7: Shore D hardness measurements of Merginol variants after 7 days of curing with MDI hardener. Values range from extremely rigid (Merginol 910 at 82) to highly flexible (Merginol 207), demonstrating the spectrum of mechanical properties available within the product line.

Chemical resistance

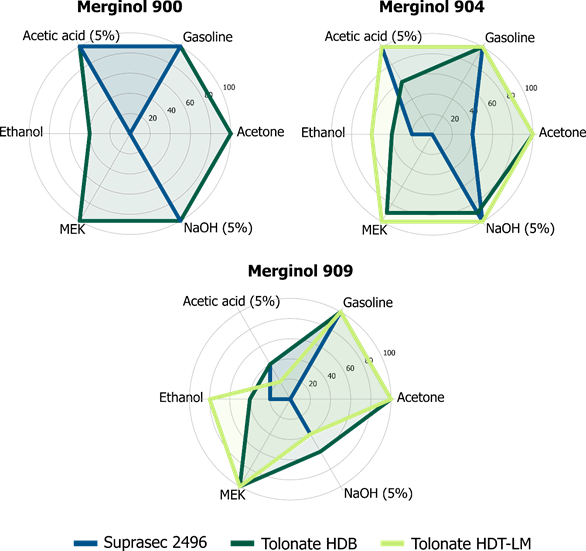

Chemical resistance is critical for many applications. We’ve rigorously tested our products against six common chemicals: Acetic Acid (5%), Gasoline, Acetone, NaOH (5%), MEK, and Ethanol.

The top performers in chemical resistance are: Merginol 900, Merginol 904 and Merginol 909.

Figure 8: Chemical resistance comparison of top-performing Merginol variants (900, 904, and 909) against six common chemicals. The radar chart shows resistance values (%) for each compound when tested with different isocyanates (Suprasec 2496, Tolonate HDB, and Tolonate HDT-LM), demonstrating their suitability for environments with chemical exposure.

Solvent-Free Formulation: Better for Products and Planet

All Merginol polyols are 100% solvent-free, allowing you to work without organic solvents. This isn’t just better for the environment and health—it also ensures a superior finish with exceptional gloss in your final products.

Sustainability Beyond the Source

Sustainability isn’t just about using renewable materials—it’s about ensuring they are responsibly sourced. That’s why we actively address challenges like deforestation risks and supply chain transparency. Our commitment extends beyond just using plant oils to ensuring the entire production process minimizes environmental impact.

Let’s Talk About Your Application

We’re ready to discuss how Merginol can enhance your specific applications. Contact us for more information, technical data, or samples to test in your formulations.

Disclaimer

The information provided above represents our best knowledge and is intended as a guideline. It does not guarantee the properties of products manufactured using our materials. Please ensure compliance with all legal and patent regulations.

FAQ

1. What exact testing procedures were used?

UV-resistance: Samples were exposed to natural outdoor conditions at our production plant in Hamburg, Germany from September to January (4 months total), positioned at a 90° angle facing south for maximum sun exposure. UV resistance was evaluated through yellowing measurements using the Δb* value on the CIE Lab* color space—a higher value indicates more yellowing. Measurements were taken using a spectral photometer (Xrite) before and after the exposure.

Viscosity: Measured using a rotational viscometer at 25°C.

Hardness: Measured using Shore Hardness tests in accordance with DIN ISO 48-4:2021-02. Tests were performed with durometer Type D at 23 °C after 7 days of curing.

Chemical Resistance: Tested according to DIN EN ISO 2812-3 (spot test method), where coated substrates were exposed to specified chemicals for 24 hours at room temperature. After exposure, samples were evaluated for visual changes (blistering, discoloration, loss of gloss) and tested for adhesion strength retention. Resistance is quantified on a 0-100% scale, with 100% representing no observable change or effect. The samples were left to cure for 7 days before the test.

2. How sustainable are plant-based polyols?

Sustainability isn’t just about using renewable materials—it’s about ensuring they are responsibly sourced. That’s why we actively address challenges like deforestation risks and supply chain transparency. Our commitment extends beyond just using plant oils to ensuring the entire production process minimizes environmental impact.

3. How can I get more information or samples?

Klick here.