Water-borne epoxy coatings for thick-layer applications

What are epoxy coatings?

Epoxy coatings are known for their mechanical strength, chemical resistance, and corrosion protection properties. They are two-component systems, consisting of Part A (resin) and Part B (hardener). These two parts must be mixed just before application. Epoxy coatings are widely used in construction, industrial maintenance, and as protective coatings.

What are thick-layer epoxy coatings?

In construction, thick-layer epoxy coatings are common in self-leveling flooring applications. These coatings are applied in layers between 2 and 5 mm, creating a smooth, seamless, and durable surface.

For high-performance areas like factories and warehouses, solvent-free epoxy systems are preferred. They provide excellent mechanical strength, chemical resistance, and abrasion resistance. However, in offices, schools, and commercial spaces, such high-performance coatings may not be necessary.

In these cases, water-based epoxy systems can be a better choice since they are:

- Easier to handle – cleaning is done with water instead of solvents

- More affordable – because water doesn’t cost much

Why thick layers are problematic

However, applying water-borne epoxy systems in thick layers presents two significant challenges:

- Water Evaporation: The water used as a solvent can remain trapped in thick layers, leading to incomplete curing.

- Volume Shrinkage: As water evaporates, the layer can shrink, potentially resulting in cracking and compromised mechanical integrity.

Thin layers: why they work

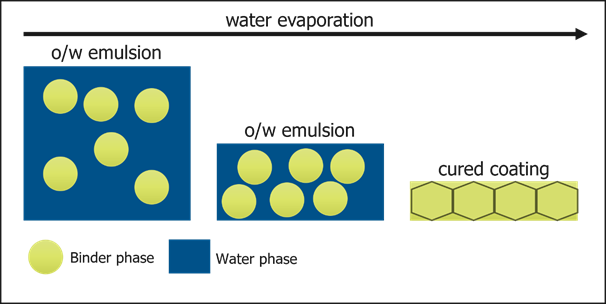

In thin layer applications (< 0.5 mm), water evaporates easily, and the coating forms a dense film. The film formation process is illustrated in Figure 1 and follows the typical process of a physically drying oil-in-water (O/W) emulsion:

- Water Evaporation: Initially, the film appears white due to light scattering by isolated emulsion particles. Over time, water evaporation concentrates polymer micelles into a densely packed structure.

- Deformation into honeycomb structure: Further water evaporation causes the particles to deform into a near-continuous honeycomb structure.

- Transmicellar diffusion: Through transmicellar diffusion, macromolecules form a clear, transparent film. The film is fully cured.

Figure 1: Illustration of the drying mechanism for a conventional water-based epoxy coating, highlighting the transition from a white film to a clear, transparent layer.

Exploring the possibilities for thick layers

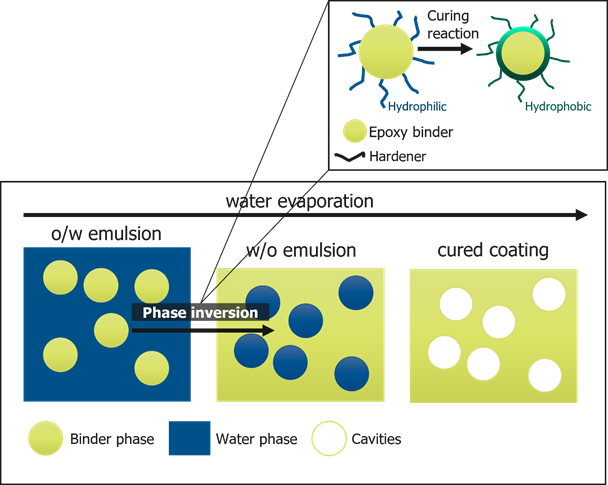

To use water-borne epoxy coatings in thick layers, it’s essential to address both water evaporation and shrinkage. This can be achieved with a curing agent that leverages a process called phase inversion. The process is illustrated in Figure 2. Here’s how it works:

1. Initial Emulsion: Oil-in-Water (O/W)

In the initial formulation, the water insoluble epoxy resin is emulsified by the hardener in the water, forming an O/W emulsion. Water acts as the continuous phase, stabilizing tiny epoxy resin droplets with the help of the curing agent (e.g. Merginamid A 210/5).

2. Curing reaction begins

As the curing process starts, the epoxy resin reacts with the curing agent, gradually forming a polymer network. The system becomes increasingly hydrophobic, shifting the balance of hydrophilic and hydrophobic forces.

3. Phase inversion: Transition to water-in-oil (W/O)

The emulsifier’s properties change from favoring O/W to favoring W/O emulsions. This phase inversion causes water to shift from being the continuous phase to being trapped in discrete pockets within the epoxy resin.

4. Encapsulation of water

The water is now encapsulated in small, evenly distributed cavities within the forming epoxy matrix. This prevents uneven shrinkage and reduces stress during curing.

5. Curing and water evaporation

Once the epoxy network is fully cured, the trapped water evaporates slowly, leaving behind cavities that correspond to the original water volume. These cavities stabilize the structure, eliminating shrinkage while allowing the coating to remain water vapor permeable.

Figure 2: Visual comparison of two systems: (Left) phase-inversion-based system showing white appearance due to cavities; (Right) non-phase-inversion system showing arching and uneven drying.

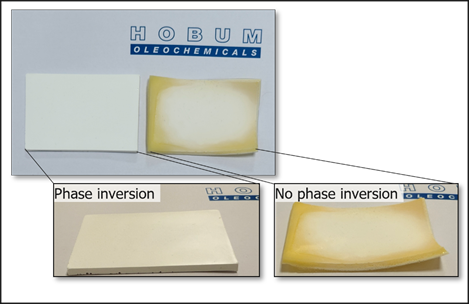

Practical example: comparing two systems

The benefits of phase inversion can be observed in the comparison of two curing agents: Merginamid A 210/5 and Merginamid A 155/2 (Figure 3)

- Merginamid A 210/5: This curing agent induces phase inversion, forming cavities that eliminate shrinkage and stress. However, in clear coats, the cavities scatter visible light, making the unpigmented sample appear white.

- Merginamid A 155/2: This curing agent does not induce phase inversion. Without phase inversion, significant stress is introduced during drying, as shown by the arching of the sample and uneven water evaporation resulting in discoloration.

Figure 3: Visual comparison of two systems: (Left) phase-inversion-based system showing white appearance due to cavities; (Right) non-phase-inversion system showing arching and uneven drying.

Considerations and trade-offs

While phase inversion offers significant benefits, it also introduces certain trade-offs that should be considered:

- Water Vapor Permeability: The resulting coating allows water vapor to pass through, which can be beneficial in some applications but problematic when used under moisture-sensitive materials like parquet flooring.

- Mechanical Properties: The mechanical properties of phase-inversion-based coatings are generally lower than those of solvent-free epoxy coatings, making them less suitable for high-load applications.

Conclusion

Phase-inversion technology enables the use of water-based epoxy coatings for thick-layer applications by carefully balancing the curing agent’s hydrophilic and hydrophobic properties. During curing, the system transitions from an oil-in-water (O/W) to a water-in-oil (W/O) emulsion, trapping water in microscopic cavities. From there, the water evaporates without inducing shrinkage.

While phase-inversion coatings may not match the mechanical strength of solvent-free epoxies, they offer the advantage of using water to clean equipment as well as a cost advantage. This makes them an excellent choice for self-leveling flooring in offices, schools, and commercial spaces.

References

- Birnbrich, P., Bourscheidt, G., Nagorny, U., Roloff, Th., Thomas, H.-J., & Sabbadini, G,. Wässrige Epoxidharzsysteme – Dünn oder Dick aufgetragen. KGK – Kautschuk Gummi Kunststoffe, March 2007, 86–93.

Disclaimer

The information provided above represents our best knowledge and is intended as a guideline. It does not guarantee the properties of products manufactured using our materials. Please ensure compliance with all legal and patent regulations.

FAQ

1. What applications are thick-layer epoxy coatings used for?

Thick-layer epoxy coatings are commonly employed in self-leveling floors for industrial environments such as factories and warehouses, where durability, chemical resistance, and abrasion resistance are critical. They are also used in commercial and institutional settings to create smooth, seamless surfaces that can handle moderate traffic while still offering a polished look.

2. What do I need to consider when using phase-inversion-based curing agents?

The key consideration is water vapor permeability. When the cured coating remains somewhat permeable to water vapor, it’s generally an advantage in settings that benefit from breathability. However, it can pose a problem if you’re installing the coating beneath moisture-sensitive materials such as parquet flooring. Ensuring compatibility with your specific floor structure or substrate is crucial.

3. Can phase inversion be used in all epoxy formulations?

No. Phase inversion depends heavily on the curing agent used. Not all epoxy-hardeners will support this process. Specially designed curing agents—like Merginamid A 210/5—are needed to achieve the phase-inversion effect. If you plan on using this technology, make sure your chosen curing agent is specifically formulated to induce phase inversion.