Mergisol: Safer bio-based diluents for epoxy resins

Meeting Industry Challenges with Sustainable Solutions

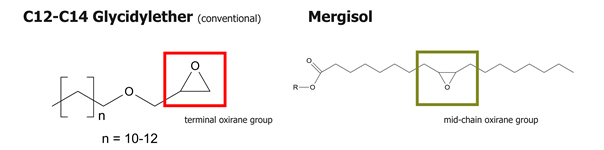

If you work with epoxy resins, you’re probably familiar with the challenges. These versatile materials are crucial for countless applications, from coatings to adhesives. But there’s a growing problem: traditional reactive diluents like C12-C14 glycidyl ethers are facing increasing scrutiny due to their reclassification as CMR substances (carcinogenic, mutagenic, or toxic to reproduction).

Mergisol products offer a solution to this challenge. They are epoxidized fatty acid esters from HOBUM and they are not subject to this reclassification. But they also work great as diluents in epoxy systems.

Figure 1: Chemical structure comparison between Mergisol and C12-C14 glycidyl ether

The Mergisol Portfolio

We’ve developed two Mergisol variants that differ primarily in one aspect – color:

- Mergisol ME 109: Our transparent option, perfect when color really matters in your application

- Mergisol ME 309: A more budget-friendly alternative with a slight yellowish tint, ideal when color isn’t a critical factor

Both variants offer identical performance properties, so you can choose the right one based on your specific needs and budget considerations.

Figure 2: Visual comparison of three reactive diluents: C12-C14 Glycidylether (left), Mergisol ME 109 (middle), and Mergisol ME 309 (right), demonstrating their color differences.

Technical Performance

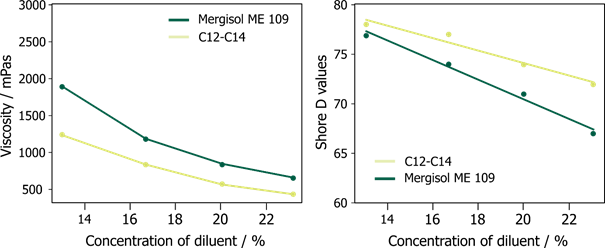

Viscosity Reduction

While Mergisol ME 109 has a higher inherent viscosity (20.5 mPas) compared to C12-C14 glycidyl ether (8.7 mPas), it effectively reduces the viscosity of high-viscosity epoxy resins. Our tests show that to achieve a comparable viscosity reduction to 1,500 mPa*s in a standard Bisphenol A resin, approximately 16 wt.% of Mergisol ME 109 is required, compared to 13 wt.% of C12-C14 glycidyl ether.

Figure 3: Comparative analysis of viscosity reduction effect (left) and Shore D hardness values (right) for Mergisol ME 109 versus C12-C14 glycidyl ether at varying concentrations in a standard Bisphenol A epoxy resin.

Migration Resistance

Despite the higher usage amount, no migration of Mergisol ME 109 was detected in test specimens. Even after 6 weeks at 50°C, the reactive diluent remained in the specimen and did not migrate to the surface.

Effect on Hardness and Hardness Development

When it comes to hardness, Mergisol ME 109 performs quite similarly to conventional diluents at concentrations below 13 wt.%. Above that threshold, you’ll notice a more pronounced decrease in Shore D hardness with Mergisol ME 109.

When we look at influence on Shore D hardness development, the systems with Mergisol ME 109 as diluent cured more slowly than conventional systems. However, after 7-8 days, they reach similar final hardness values with Mergisol ME 109 samples showing only slightly lower Shore D values (depending on the curing agent used).

Figure 4: Shore D hardness development over time for different Merginamid hardener systems, illustrating how Mergisol ME 109 formulations compare to conventional C12-C14 glycidyl ether systems in terms of curing rate and final hardness.

Reactivity considerations

An important difference: When mixed with Merginamid A 380 (our fastest epoxy hardener), Mergisol showed minimal reactivity over 12 days, while the conventional C12-C14 glycidyl ether reacted significantly, as shown by increasing viscosity.

Therefore, we recommend excluding the EEW (Epoxy Equivalent Weight) of Mergisol when determining mixing ratios of hardeners.

Figure 5: Reactivity comparison over 12 days between Mergisol ME 109 and C12-C14 glycidyl ether when mixed with Merginamid A 380 hardener. The graph demonstrates that Mergisol ME 109 shows minimal reactivity with the hardener (minimal viscosity increase), while C12-C14 glycidyl ether shows significant reactivity (substantial viscosity increase).

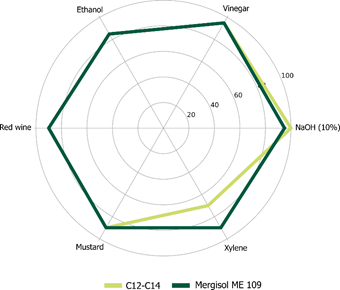

Chemical Resistance

Despite this, the chemical resistance is not affected as our tests show. Mergisol ME 109 maintains excellent chemical resistance profiles, matching that of samples with C12-C14 glycidyl ether.

Figure 6: Chemical resistance comparison of epoxy systems formulated with Mergisol ME 109 versus C12-C14 glycidyl ether, showing resistance percentages against common chemicals including acids, bases, and solvents.

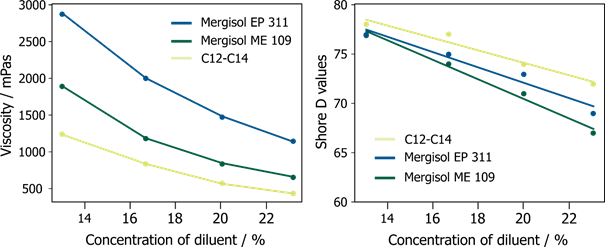

Future Developments

We are currently working on a new Mergisol variant: Mergisol EP 311. It is based on the same epoxidized fatty acid ester but with a different ester group. This provides better compatibility in some systems, though with somewhat reduced dilution efficiency. Mergisol EP 311 shows promising results in terms of Shore D hardness development, making it an excellent alternative if you’re experiencing compatibility issues with Mergisol ME 109. However, it’s important to note that Mergisol EP 311 is currently an experimental product and isn’t yet REACH-registered. Though we’re planning to register it in the future.

Figure 7: Comparative analysis of Mergisol ME 109 and the experimental Mergisol EP 311, highlighting differences in dilution efficiency and Shore D hardness.

Conclusion

Mergisol represents a significant advancement in epoxy formulation technology, offering you:

- Freedom from reproductive toxicity concerns

- Comparable performance to C12-C14 glycidyl ether

- Reduced environmental impact through bio-based sourcing

With regulatory requirements getting stricter every year, Mergisol gives formulators a future-proof solution that doesn’t force you to compromise on performance, safety, or sustainability.

Want to try it out? For sample requests or more information about the Mergisol product line, visit our website at HOBUM.de and get in touch with our technical team. We’d be happy to help you find the right solution for your specific needs.

Disclaimer

The information provided above represents our best knowledge and is intended as a guideline. It does not guarantee the properties of products manufactured using our materials. Please ensure compliance with all legal and patent regulations.

FAQ

1. How can I get more information or samples?

Klick here.

2. Will switching to Mergisol require significant reformulation of my existing epoxy systems?

Transitioning to Mergisol is relatively straightforward. You’ll need to make two main adjustments: using a slightly higher amount of Mergisol compared to conventional diluents and excluding Mergisol’s EEW when calculating your hardener ratios.

In the rare cases where compatibility issues arise, our experimental Mergisol EP 311 often provides an excellent solution. Even though the product is not yet REACH registered, we’re prepared to do that if the customer demand warrants it.

3. How does the cost of Mergisol compare to conventional C12-C14 glycidyl ether diluents?

Our Mergisol products are designed to be cost-competitive with conventional diluents, especially when considering the total value proposition. In many cases, the slight price difference is offset by reduced regulatory compliance costs and marketing advantages of using safer, bio-based materials.

Mergisol ME 109, our transparent version, commands a small premium due to its enhanced aesthetic properties and a more complex production process.

4. How do Mergisol products compare to other bio-based alternatives on the market?

Unlike some plant-based alternatives, Mergisol maintains great performance with no migration and only a minimum plasticizing effect. This is due to the optimized chemical structure of the product. In addition, Mergisol ME 109 is transparent and lacks the yellowish appearance that is common in many other plant-based alternatives.

5. What exact testing procedures were used?

Viscosity: Measured using a rotational viscometer at 23°C.

Hardness: Measured using Shore Hardness tests in accordance with DIN ISO 48-4:2021-02. Tests were performed with durometer Type D at 23 °C after 7 days of curing.

Chemical Resistance: Tested according to DIN EN ISO 2812-3 (spot test method).Coated substrates were exposed to the specified chemicals for 24 hours at room temperature. After exposure, samples were evaluated for visual changes (blistering, discoloration, loss of gloss) and tested for reduction in Shore D hardness. Resistance is quantified on a 0-100% scale, with 100% representing no observable change or effect. The samples were left to cure for 7 days before the test.