How to navigate sustainability

Everything’s sustainable

In today’s world, sustainability is a complicated chain of regulations, obligations and bureaucracy. Everything needs to be compliant, and anything is claimed to be green. It’s forced on industries across the globe which leads to more and more capacity being absorbed.

But is it worth the effort? Absolutely. We can discuss the bureaucracy part but there is no doubt that sustainability will drive innovations and set up our industry for long term success. This is also highlighted by the recent IPCC report showing that delaying action on climate change only raises future costs and preserves inefficiency, while swift action sparks innovation and long-term success. Therefore, forward-thinking companies know that sustainability isn’t a box to tick; it’s a strategy to embrace.

An example from the chemical industry

The chemical industry, as a major consumer of natural resources, carries significant responsibility for adopting sustainable practices. As a result, the supply chain shifts from fossil-based to plant-based materials. A good example are polyurethanes (PU). A versatile material found in countless everyday products. Plant-based polyols, like those made from soybean oil, can replace fossil-based polyols. These polyols are used to make polyurethane based products. But is plant-based always more sustainable? Let’s explore how soybean-based polyols are made.

From soybean cultivation to polyol production

The process starts with the cultivation of soybeans. They grow in various parts of the world, with major producers in Brazil and the United States. Once harvested, the soybeans are processed to extract the oil, which forms the basis of our polyols. The extracted oil undergoes several steps to remove impurities and to ensure a high-quality product that we receive as a raw material.

The refinement process where the soybean oil is transformed into a polyol starts with epoxidizing the soybean oil. Following this, the epoxidized oil reacts with a multifunctional alcohol. A polyol is born.

Figure 1: From soybean to polyol

But how sustainable are these polyols really?

The use of biobased raw materials does not automatically solve the issue of sustainability. The origin of the raw materials matters. This becomes clear when we take a closer look at our example.

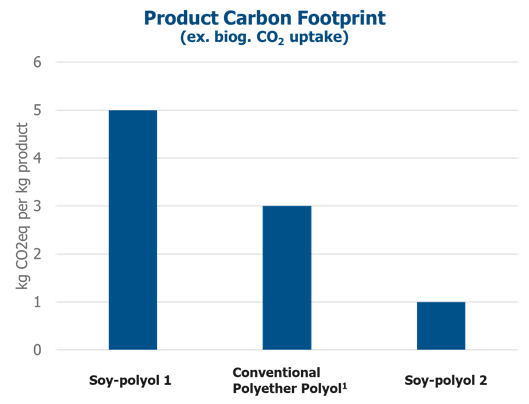

The Product Carbon Footprint (PCF) includes all greenhouse gas emissions over a product’s lifecycle. For simplicity, the industry has agreed to calculate the PCF using the “cradle-to-gate” approach. This means that the calculation boundaries end at the factory gate, leaving it up to the customer to complete the calculation. For our soy-based polyols, the PCF primarily consists of two components: the CO₂ emissions from the cultivation and processing of soybeans, and the energy required for their refinement in our production facilities.

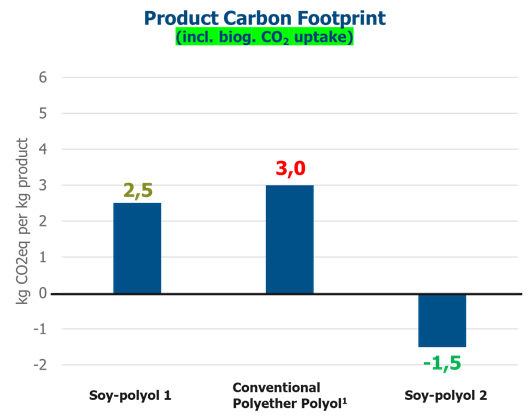

Figure 2 provides an example of such a calculation for three different polyols. Let’s take a closer look at the underlying factors.

Figure 2: PCF comparison of three different polyols

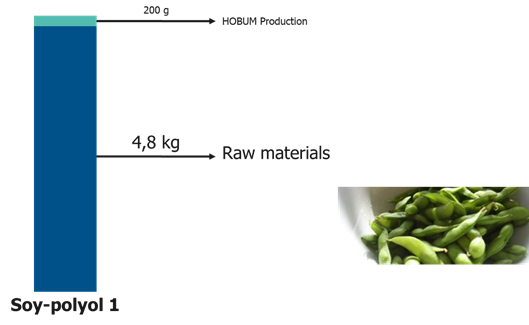

Figure 3 breaks down the PCF of “Soy-polyol 1”. It shows that the most significant contributor to the PCF is the used raw materials, i.e. soybean oil.

Figure 3: Breaking down the Product Carbon Footprint (PCF) of soy-polyol 1

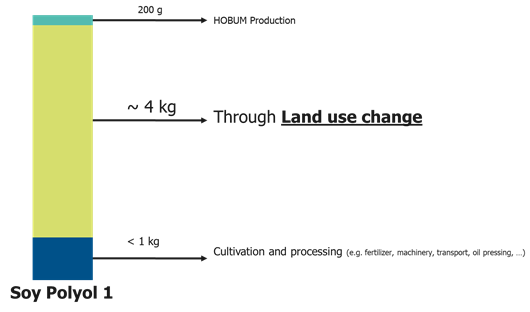

At first glance, it might seem that long distance transportation of soybeans would be the major contributor to the emissions. However, the analysis shows that land use changes – particularly deforestation – have a much greater impact. The carbon emissions from clearing land for agriculture often exceed those from transporting the soybeans significantly. In fact, one hectare of rainforest can store approximately 600 tons of CO22, which is released immediately as when the area is deforested. This deforestation impact accounts for 80 % of the total emissions, equating to 4 kg of CO₂ per kilogram of soybean oil (see Figure 4).

Figure 4: Breaking down the Product Carbon Footprint (PCF) of soy-polyol 12

More than one sustainable alternative: NEO and RTRS soybean oil

At HOBUM, we are acutely aware of the impact of our raw materials. We believe that sustainability goes beyond reducing emissions at our factory—it’s about making informed decisions across the entire supply chain. This is why we developed our NEO (New Environmental Option) products. The soy used in these products originates from deforestation-free regions within the EU and is cultivated under strict environmental and social standards. This is backed by certifications like the „Donau Soja“ standard, which ensures deforestation-free cultivation in Europe while respecting local ecosystems and biodiversity.

In addition, we offer products certified under the RTRS (Round Table on Responsible Soy) standard. Unlike the NEO products, RTRS products follow a mass balance approach, allowing for greater flexibility in sourcing the soybean oil.

The elephant in the room – Are soy-polyols worse than conventional petrochemical polyether polyols?

When taking another look at Figure 2, we notice that the PCF of Soy-polyol 1 is increased by 2 kg compared to the PCF of the conventional polyether polyol that originated from crude oil. Can that be right?

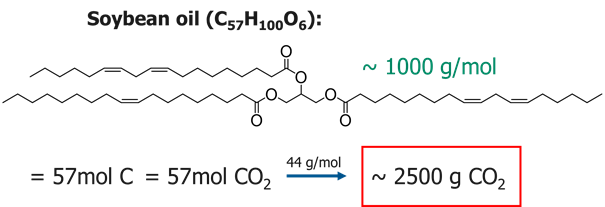

One of the key advantages of plant based raw materials, such as those based on soybeans is their ability to absorb CO2 during the growth phase of the plant. As soybeans grow, they naturally absorb carbon dioxide from the atmosphere through the process of photosynthesis. A simple back-of-the-envelope calculation in Figure 5 shows that this offset is as large as approximately 2.5 kg CO2 per kg soybean oil. This was not yet considered in the comparison in Figure 2.

Figure 5: Back of the envelope calculation for biogenic CO2 uptake of soybean oil

Taking this offset into account we get the actual PCF numbers for our soybean polyol example, shown in Figure 6.

Figure 6: PCF comparison of three different polyols incl. biog. CO2 uptake

Conclusion

Sustainability is a complex topic that extends far beyond the use of renewable raw materials. Eventually the origin of these materials matters most. Land-use changes, especially due to slash-and-burn practices, significantly contribute to emissions. Certifications such as NEO and RTRS not only support HOBUM but also help our customers identify and consciously choose truly sustainable products.

References

- ISOPA. (2021, April). Eco-profile of long and short chain polyether polyols for polyurethane products. International Isocyanate Institute. https://plasticseurope.org/sustainability/circularity/life-cycle-thinking/eco-profiles-set/ (accessed 03.04.24).

- Alcock, T. D., Salt, D. E., Wilson, P., & Ramsden, S. J. (2022). More sustainable vegetable oil: Balancing productivity with carbon storage opportunities. Science of the Total Environment, 829(2022), 154539 https://doi.org/10.1016/j.scitotenv.2022.154539

FAQ

1. Are plant-based polyols always more sustainable than fossil-based alternatives?

Not necessarily. While plant-based materials can offer advantages like renewable sourcing and CO₂ absorption during plant growth, other factors like land use changes, deforestation, and transportation emissions can significantly impact their overall sustainability. A comprehensive analysis, including the Product Carbon Footprint (PCF), is essential to determine their true environmental impact.

2. How does land use change, like deforestation, impact the sustainability of soy-based polyols?

Deforestation is a major contributor to carbon emissions. When forests are cleared for agriculture, the carbon stored in the trees and soil is released into the atmosphere. This can account for up to 80% of the emissions associated with soy-based polyols. Sustainable sourcing practices, like using deforestation-free soybeans, are critical to mitigating this impact.

3. What certifications should I look for to ensure that the soybean oil I use is truly sustainable?

Certifications like the Round Table on Responsible Soy (RTRS) and Donau Soja ensure that soy is sourced sustainably. These certifications verify that the soybeans were grown without deforestation, meet rigorous environmental standards, and support ethical farming practices. They help companies and consumers make more informed, environmentally conscious choices.

4. What about a ‚Food, Feed, Fuel‘ discussion?

You are absolutely correct—the ‚Food, Feed, Fuel‘ issue is incredibly important. However, we intentionally left it out of this post to give it the focused attention it deserves in a dedicated article. This allows us to explore its complexities and implications in greater depth.